Realization of the DB Precast Line

The construction of the Terrazzo Precast takes place in the laboratory with the prefabrication of normal materials such as aggregates and marble powder of various sizes and shades, mixed with special natural binders such as white and/or gray cement, without the use of resins and with the addition of only anti-shrinkage liquids.

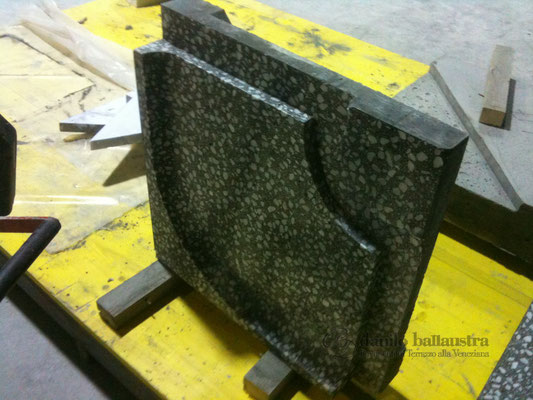

The castings are made on formworks or frames, depending on the piece to be obtained, and after a minimum maturation are processed in the laboratory to obtain the panels / slabs finished.

The thickness of the slabs produced for the "DB Precast" line varies according to their dimensions, following the project specifications. Up to 60/70 cm² of surface area, the processing can be optimized with only 2 cm of thickness, while for larger dimensions the panel thickness is increased from 3 to 8 cm. It is also possible to make panels of considerable dimensions in a single slab, adapting the due thickness to allow the safety in the fixing of these elements, taking into account the considerable weight to be supported, which can even reach 450/550 kg. The installation of these heavy panels is done by means of iron frames incorporated into the casting and then welded on back-structures properly fixed to the masonry. Danilo Ballaustra's teams of professionals install the slabs on the basis of the executive project presented by the professional and subsequent on-site survey carried out before work begins. The technical advice of the owner Danilo Ballaustra is also very important. During the design phase, Danilo Ballaustra carries out an in-depth study of possible construction problems, immediately identifying all the solutions necessary to obtain the best final result.